About

us Products Services Contact Security Forces Motorsports News & Events

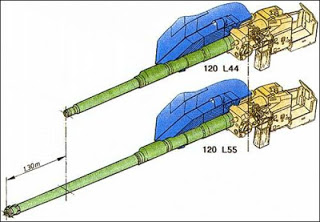

Gun Extension on Leopard 2A4 120mm L44 Gun to L55

Gun using Rotational Fiction Welding Process Technology

1) Acquired 2 new 120mm L44 guns barrels.

2) Cut one gun to length at 1.31 meters long.

(or buy from European Armour Union Pte Ltd in Singapore)

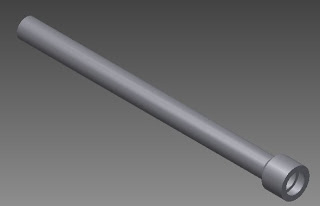

3) Sand cast or forge a bell end on one end of the

1.31meters short barrel guns using the original remaining gun material.

(Bell End provide ultimate Fit of Firing failure proof).

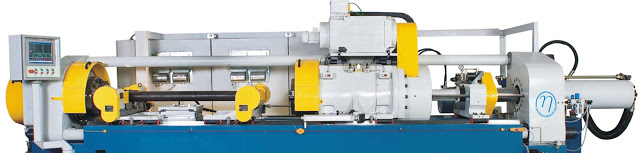

4) Clamp the new L44 gun barrel & the 1.31meters short

barrel guns onto the chuck of the Rotational fiction welding machine.

5) Heat up L44 gun end & the bell end of

the 1.31meters long gun with 2 piece removable top & bottom black smith oven

with bottom tray filled with coal & blasted with gas & pure oxygen for 30

minutes till it reaches 2,500 degree.

6) Use infra-red temperature scanner to

capture gun end temperature & remove the 2 piece top

& bottom mobile oven.

7) Completed the joining process by rotating the 1.31 meters gun at high speed with

full contact with the L44 gun, when both ends reach 3,200 degree stop the

rotational chuck & apply transverse compressive pressure

between the 2 guns to forge weld it together.

8) The bell ends of the 1.31 meter guns will

enlarge slightly due to the bulging joint of the rotational fiction welding process

which ultimately strengthen the gun joint diameter compressive forces use for

high pressure firing (Bell end provide ultimate Fit of Firing failure

proof).